Engineering

A machines’ global performance depends on 3 main factors such as :

• the mechanical perfection (machine body, and mechanical parts in motion),

• the sensors and actuators (reliable electronics, computational power and interfaces),

• and the advanced programming and CNC control strategies involving specific algorithms.

We follow our customers in their challenge in manufacturing performent machines. Starting from the mechanical design we help them in a common challenge sprit to find the optimal machining performance by :

• selecting the electrical or hydraulic servo motor, servo drive, gearbox and linear transmission equipments,

• realising specific interfaces for process related actuators and sensors,

• proposing a suitable LYNCA – CNC controller able to execute fast algorithms,

• developing specific programming cycles for motion and logic control

• and user friendly modern programming interfaces.

• Commissionning and test support

• Maintenance support

This requires a mutual understanding of the objectives, having complementary technical competences and involvement and trust.

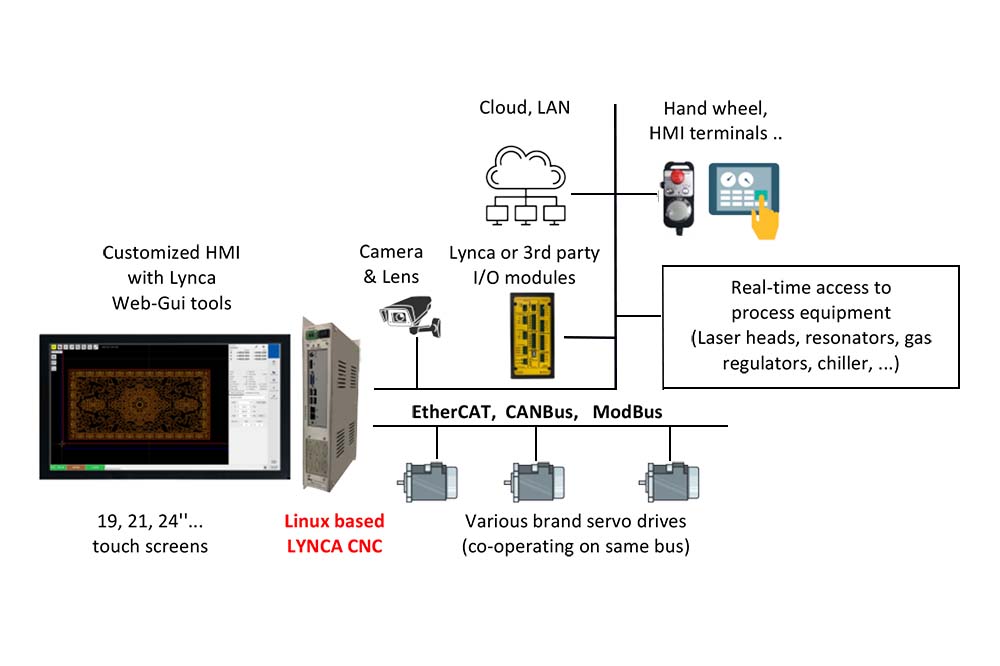

Open architecture CNC

The optimal solution is only possible with an Open-Architecture Control system environment. Since more than 20 years of design experience LYNCA – CNC represents today a very performent solution providinag openness in :

• Motion control level with advanced motion language open to extensions with new codes for specific cycles,

• Logic control level, thanks to the built-in performent LPC (IEC1131 compliant PLC library with C language compiler),

• Real-Time specific Process interfaces level, with possibility to integrate specific protocols for I/O and logic signal interfaces in Motion and Logic cycles,

• User interface development levels, thanks to Web GUI tools with Java script tools.

Considering this open platform, LYNCA – CNC is able to run at the same time with various real-time buses (EtherCat, CanBUS, Modbus, ..) interfacing various sensor or actuator or process equipment. It’s possible to run :

• on the same bus different manufacturers’ servo drives,

• execute parallel loading, machining and unloading cycles.

• manage user interface and remote access (CNC screen, parealle tablets, smart phones on the same network.)